In today’s fast-paced business environment, maintaining high quality while continuously improving processes is essential for success. A Quality Management System (QMS) ensures that organizations meet customer requirements and regulatory standards while improving operational efficiency. One of the core methods used to achieve this is the PDCA cycle, also known as the Deming Cycle. This blog explores the connection between PDCA and QMS, and how it leads to continuous improvement and quality assurance.

Understanding the PDCA Cycle?

The Plan-Do-Check-Act (PDCA) cycle is a key methodology in quality management systems (QMS) that facilitates continuous improvement. When integrated into QMS, PDCA provides a structured framework for refining processes, meeting quality objectives, and enhancing customer satisfaction. This approach plays a crucial role in driving long-term success within organizations.

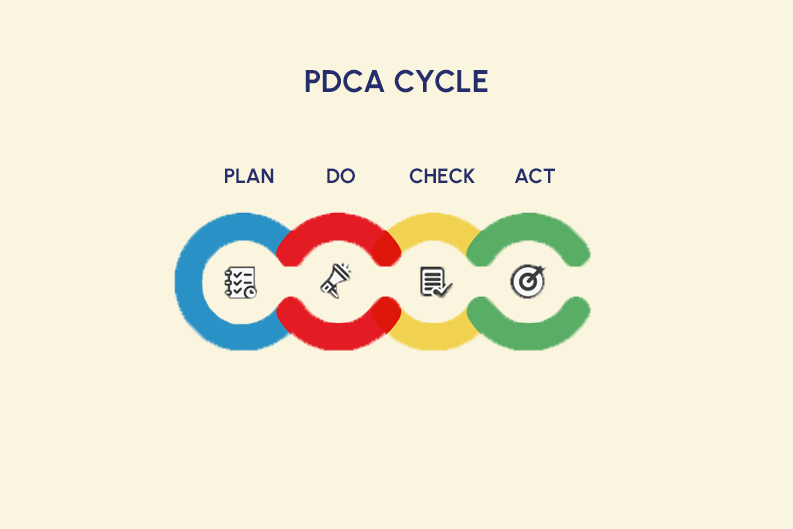

PDCA is a systematic, iterative process aimed at solving problems and improving operations. It consists of four stages:

- Plan: Identify the issue, collect relevant data, and create a plan to address the problem.

- Do: Implement the plan on a small scale to test its effectiveness.

- Check: Evaluate the results to see if the plan achieved the desired outcome.

- Act: If successful, standardize the solution; if not, adjust the plan and repeat the cycle.

This cycle fosters a culture of continuous improvement by ensuring that every change is thoroughly tested and optimized before full-scale implementation.

The Role of PDCA in Quality Management Systems

PDCA is an integral part of many quality management standards, such as API Specification, and ISO standards, where the emphasis is on systematic, repeatable processes. In QMS, the PDCA cycle is applied to improve key areas, such as product design, production processes, and customer service.

By integrating PDCA into QMS, organizations can:

- Regularly evaluate performance.

- Identify areas that need improvement.

- Implement changes that enhance process efficiency and effectiveness.

How PDCA Enhances Continuous Improvement in QMS

Continuous improvement is a key principle of most quality management systems. The PDCA cycle provides a structured approach to achieving this:

- Monitoring and Measurement: The Check phase of PDCA aligns with QMS requirements to monitor and measure processes, ensuring that they meet defined objectives.

- Corrective Actions: If an issue is identified during the Check phase, PDCA allows organizations to take corrective actions, ensuring that non-conformities are addressed quickly.

- Real-World Example: For instance, a manufacturing company might use PDCA to reduce defects in its production line. By planning the improvement, testing it, reviewing the outcomes, and then acting on the data, the company enhances its process, meeting QMS requirements while continuously improving.

Implementing PDCA in Your Organization’s QMS

To successfully implement PDCA within a QMS framework, organizations can follow these steps:

- Training: Educate employees on the principles of PDCA and how it relates to the quality management system.

- Start Small: Apply the PDCA cycle to specific processes or departments before rolling it out organization-wide.

- Use Data: Leverage data and metrics to make informed decisions at each stage of the PDCA cycle.

- Review and Adjust: Regularly review the performance of processes and adjust strategies as needed to maintain continuous improvement.

Challenges in implementation may include resistance to change or lack of resources. However, by encouraging a culture of quality and improvement, organizations can overcome these barriers.

Benefits of Connecting PDCA with QMS

The integration of the PDCA cycle with Quality Management Systems offers several benefits, including:

- Process Efficiency: PDCA helps identify inefficiencies and implement process improvements, leading to more streamlined operations.

- Data-Driven Decisions: The structured nature of PDCA ensures that decisions are based on data and facts, minimizing the risk of errors.

- Customer Satisfaction: Continuous improvement through PDCA means consistently meeting or exceeding customer expectations, which enhances satisfaction and loyalty.

- Compliance: PDCA supports compliance with quality management standards like ISO 9001, which require regular reviews and improvements.

Conclusion

The PDCA cycle is a powerful tool for ensuring continuous improvement and optimizing the effectiveness of a Quality Management System. By connecting PDCA with QMS, organizations can improve efficiency, enhance customer satisfaction, and maintain compliance with industry standards. If your organization hasn’t yet integrated PDCA into your quality strategy, now is the time to start.